![]() Accurate alignment of the mold with the first segment in billet, bloom or near-net shape casters impacts surface quality during steel production. Improper transition can lead to surface and internal quality issues as well as increased mold wear, and potential breakout conditions. In recent years, the demand for a quick and accurate method for measuring the alignment spurred the advancement in this technology.

Accurate alignment of the mold with the first segment in billet, bloom or near-net shape casters impacts surface quality during steel production. Improper transition can lead to surface and internal quality issues as well as increased mold wear, and potential breakout conditions. In recent years, the demand for a quick and accurate method for measuring the alignment spurred the advancement in this technology.

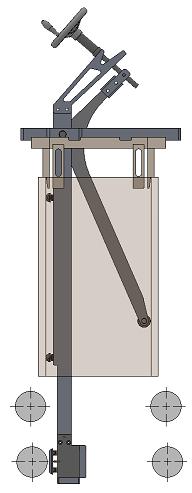

ST170 Alignment Gauge

The ST170 alignment gauge is a custom measurement tool designed to accurately measure the alignment between the mold and first segment in billet and bloom casters. Historically, measuring the transition was time consuming and difficult – generally performed by using a straight bar and feeler gauges or other mechanical methods. If misalignment is detected, the segment is adjusted below the mold and measurements are recorded down to the thousandths of an inch.

The ST170 alignment gauge is a custom measurement tool designed to accurately measure the alignment between the mold and first segment in billet and bloom casters. Historically, measuring the transition was time consuming and difficult – generally performed by using a straight bar and feeler gauges or other mechanical methods. If misalignment is detected, the segment is adjusted below the mold and measurements are recorded down to the thousandths of an inch.

The unique design of the ST170 makes it possible for a single technician to measure the alignment quickly and without error. The gauge can be quickly inserted and locked into position in the mold and measurements are taken within several minutes – saving valuable time and resources. The measurement sensor is mounted in the lower portion of the gauge, extending down into the first segment to contact the rolls. Resulting alignment data is displayed on a digital readout so the technician can quickly evaluate the transition and make adjustments as necessary.