![]() Sequence Technologies' systems measure steel slab width, thickness and edge profile using non-contact, laser-based technologies to optimize the continuous casting and hot mill processes. Our engineers develop reliable measurement systems that sustain daily use in the mill's extreme operating conditions.

Sequence Technologies' systems measure steel slab width, thickness and edge profile using non-contact, laser-based technologies to optimize the continuous casting and hot mill processes. Our engineers develop reliable measurement systems that sustain daily use in the mill's extreme operating conditions.

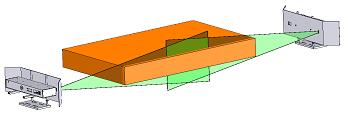

ST202 WidthVIEW

The ST202 WidthVIEW & ST202t (for thin slabs) systems accurately measure a slab's narrow face edge profile, width and thickness to control slab dimensions for Quality Assurance and optimizing caster output. Using a pair of laser profile sensors, the ST202 systems sample dimensions ten times per second, with upwards of 480 data points per side, to accurately characterize slab shape. Our proprietary software algorithms delivers information needed by operators to optimize casting performance and machine yield.

The ST202 WidthVIEW & ST202t (for thin slabs) systems accurately measure a slab's narrow face edge profile, width and thickness to control slab dimensions for Quality Assurance and optimizing caster output. Using a pair of laser profile sensors, the ST202 systems sample dimensions ten times per second, with upwards of 480 data points per side, to accurately characterize slab shape. Our proprietary software algorithms delivers information needed by operators to optimize casting performance and machine yield.

Unlike other profile systems that use complex optics and moving components, the ST202's profile lasers contain no moving parts, enhancing  reliability in harsh steel mill environments. The PC's user interface continuously displays the slab edge profile, distance from the centerline of the machine, minimum and maximum width, and thickness. Customers typically interface with the ST202 system through standard third party client software such as RS Lynx or Kepware for long term quality assurance reviews.

reliability in harsh steel mill environments. The PC's user interface continuously displays the slab edge profile, distance from the centerline of the machine, minimum and maximum width, and thickness. Customers typically interface with the ST202 system through standard third party client software such as RS Lynx or Kepware for long term quality assurance reviews.